UIG

RESONANT TESTERS

UIG-series resonant testers are designed for high-voltage testing of high-capacitance objects such as generator stator windings, busbars, cables etc. The testing can be performed with either a DC or an AC voltage at industrial frequency, in automatic or semi-automatic modes.

All UIG resonant testers are built to order according to customer’s specifications.

TESTING GENERATORS ON THEIR OPERATING FREQUENCY

Testing objects on their operating frequency is best because it allows to test in the conditions close to operating.

Operating principle of a resonant reactor included in UIG tester is based on variable inductance which is achieved by adjusting the air gap between the coils. Current resonance effect allows to significantly decrease the power consumption (generally, by 20 times and more) and, subsequently, decrease the necessary power of the step-up transformer voltage regulator, hence reducing the weight and dimensions of the system as a whole.

Due to significantly lower input power requirements, resonant test systems are most practical solution for testing high-capacitance objects.

AUTOMATIC TESTING MODE

All test cycles can be carried out in an automatic mode, which minimizes the operator error: it is only necessary to correctly connect the system to an object, find the resonanse zone and start the program.

Optionally, the system may be controlled using a remote control.

AUTOMATIC RESONANCE HOLDING

UIG systems create a test voltage on the capacitive load by maintaining current resonance in a parallel circuit, formed by a resonant reactor and the insulation capacitance of the object under the test.

The resonance is held automatically over the entire test voltage range.

HIGH QUALITY FACTOR

A quality factor (or Q-factor) is the ratio of the energy stored in the resonant system to the energy lost by the system per one oscillation cycle. Q-factor characterizes the quality of a resonant system: the higher the Q-factor is, the less energy is lost in the system per oscillation.

The quality factor of UIG systems is up to 60, meaning that the power consumption is approximately 1/60 of the reactive power required for a test object.

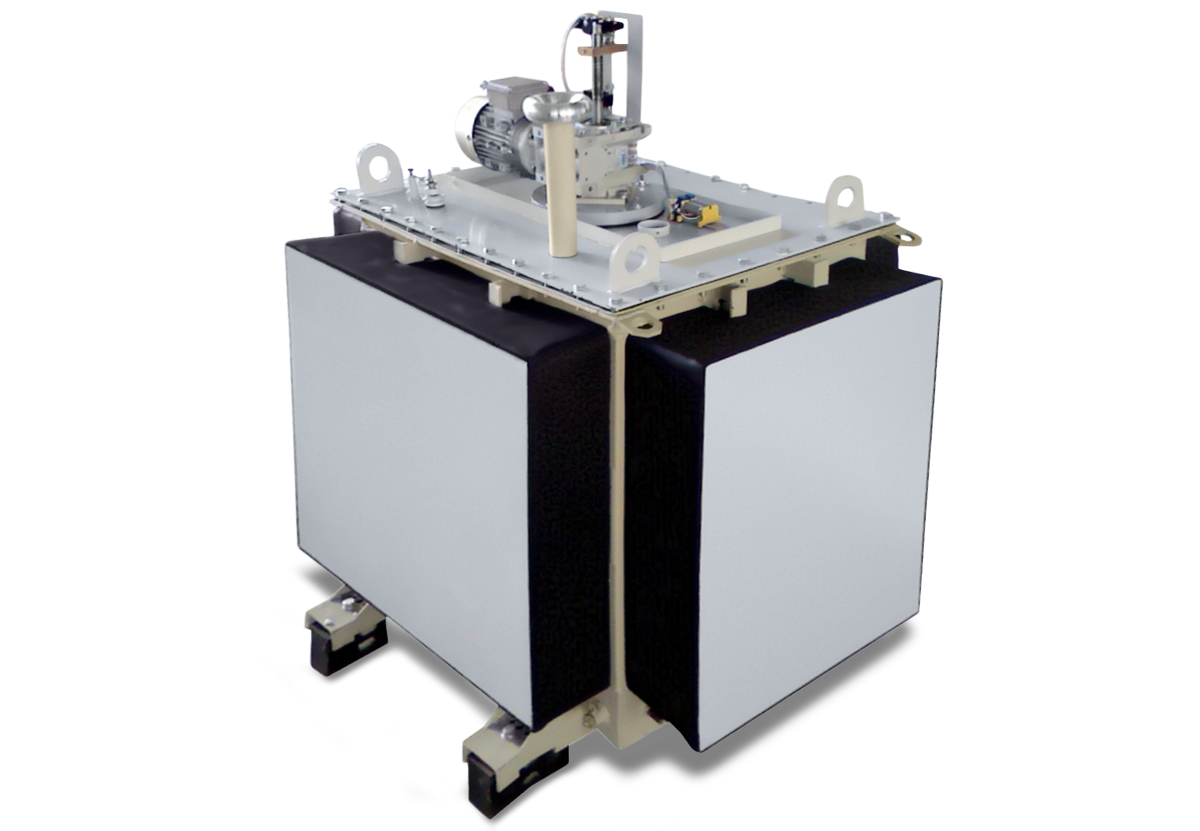

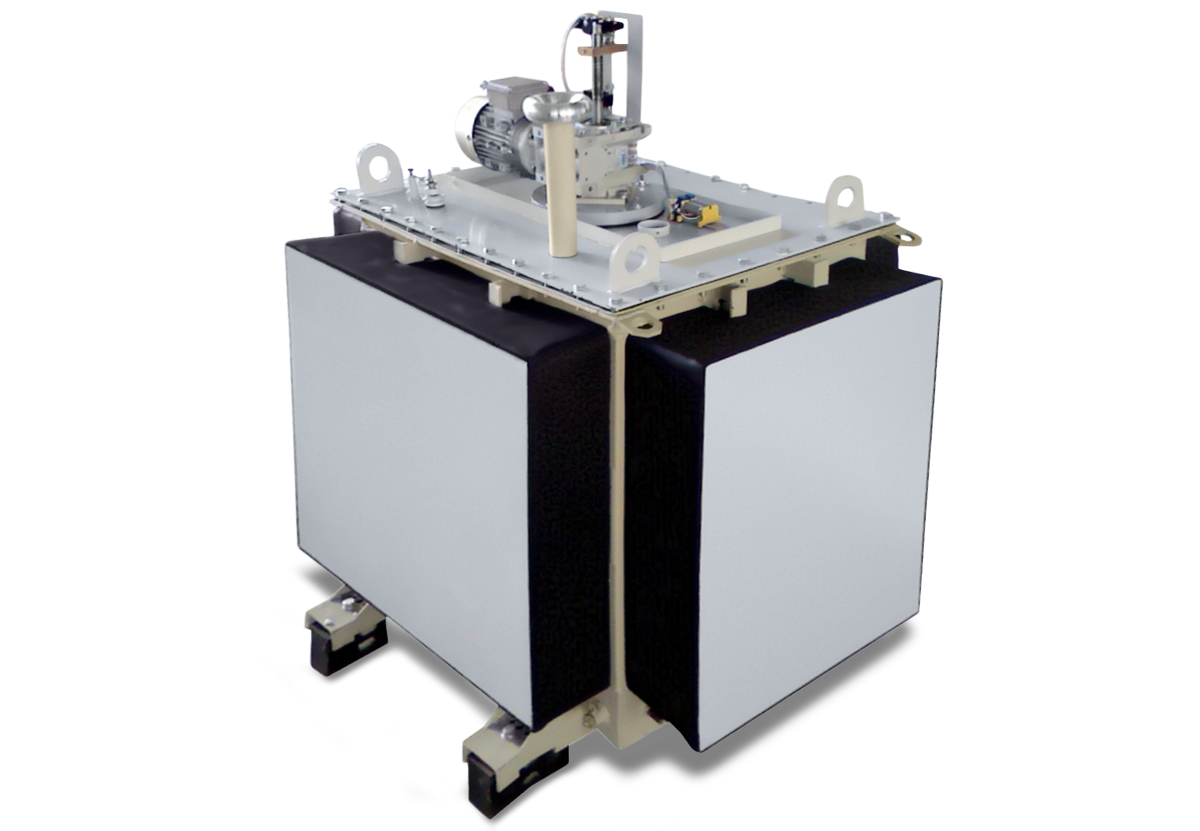

COMPACT DESIGN

UIG systems stand out from other resonance testers by their compact design – UIG is a single-module system weighing no more than 3000 kg.

Such design minimises the deployment time, simplifies its maintenance and increases operator safety level.

SAFETY FEATURES

✓ Continuous grounding monitoring module.

✓ Input and output overcurrent protection, input over- and under-voltage protection, as well as phase or neutral continuity monitoring.

✓ Grounding short-circuiter discharging the object capacitance in an emergency or scheduled system shutdown.

TOUCH CONTROL

UIG testers are equipped with a touch-sensitive, colour screens that display the status of sensors and protective devices, calibration parameters, test parameters, diagnostic information and measurements results.

Digital interface also allows to store and view test reports.

COMPLETED PROJECTS

All UIG resonant testers are tailor built to customers’ specifications. The table below shows some of the completed projects:

|

Model |

Power, kVA |

Test object capacitance, μF |

Operating site |

|

UIG-25/50/70-180 |

180 |

0.2 … 0.8 |

Ust-Khantayka HPP, Russia |

|

UIG-15/225 |

225 |

0.01 … 6 (at 7.5 kV) |

ZAO Bеltelecabel, Belarus |

|

UIG-35/70/80-250 |

250 |

0.2 … 0.6 |

Zatonskaya TPP, Russia |

|

UIG-35/70/80-250 |

250 |

0.2 … 0.6 |

Shaturskaya GRES, Russia |

|

UIG-35/50/70-315 |

315 |

0.2 … 0.8 |

Dniester PSPP, Ukraine |

|

UIG-35/400 |

400 |

0.2 … 1 |

Boguchansk HPP, Russia |

|

UIG-50-500 |

500 |

0.15 … 0.7 |

Rogunsk HPP, Tajikistan |

|

UIG-40/80/100-500 |

500 |

0.25 … 0.94 |

JSC Atomtechenergo, Russia |

|

UIG-30/60/85-700 |

700 |

0.5 … 2.5 |

Volga HPP, Russia |

|

UIG-35/70/80-250 |

250 |

0.2 … 0.6 |

Shaturskaya GRES, Russia |

|

UIG-35/70/100-750 |

750 |

0.3 … 1.5 |

Sayano-Shushenskaya HPP, Russia |

|

UIG-35/70/100-800 |

800 |

0.3 …1.8 |

Krasnoyarsk HPP, Russia |

|

UIG-30/60/85-900 |

900 |

0.7 … 2.8 |

Volga HPP, Russia |

|

UIG-35/70/100-1400 |

1400 |

0.01 … 1.5 |

Sayano-Shushenskaya HPP, Russia |

* Products specifications are subject to change without notice. *