ETL-8

COMPACT CABLE TEST VAN

Van-based cable test and fault location system ETL-8 is used for testing cable insulation and locating cable faults using a variety of methods.

Due to its compact size, ETL-8 may be installed in a minivan, yet it is a fully‑featured cable test and fault location system which incorporates burn module and surge wave generator, and is capable of faults pre‑location and cable insulation testing with high DC voltage.

FITS INTO COMPACT VEHICLES

ETL-8 can fit into most minivans, which is an ideal solution for cable fault location in dense urban areas and on narrow streets.

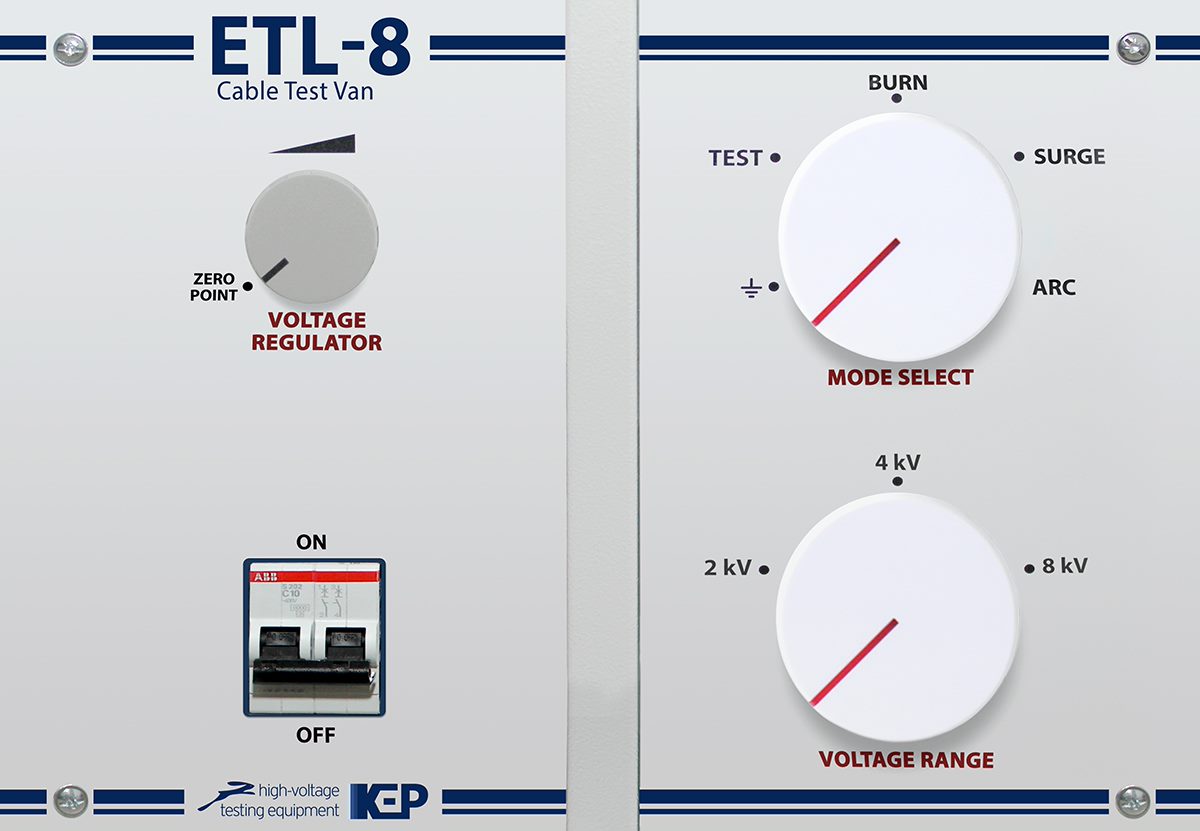

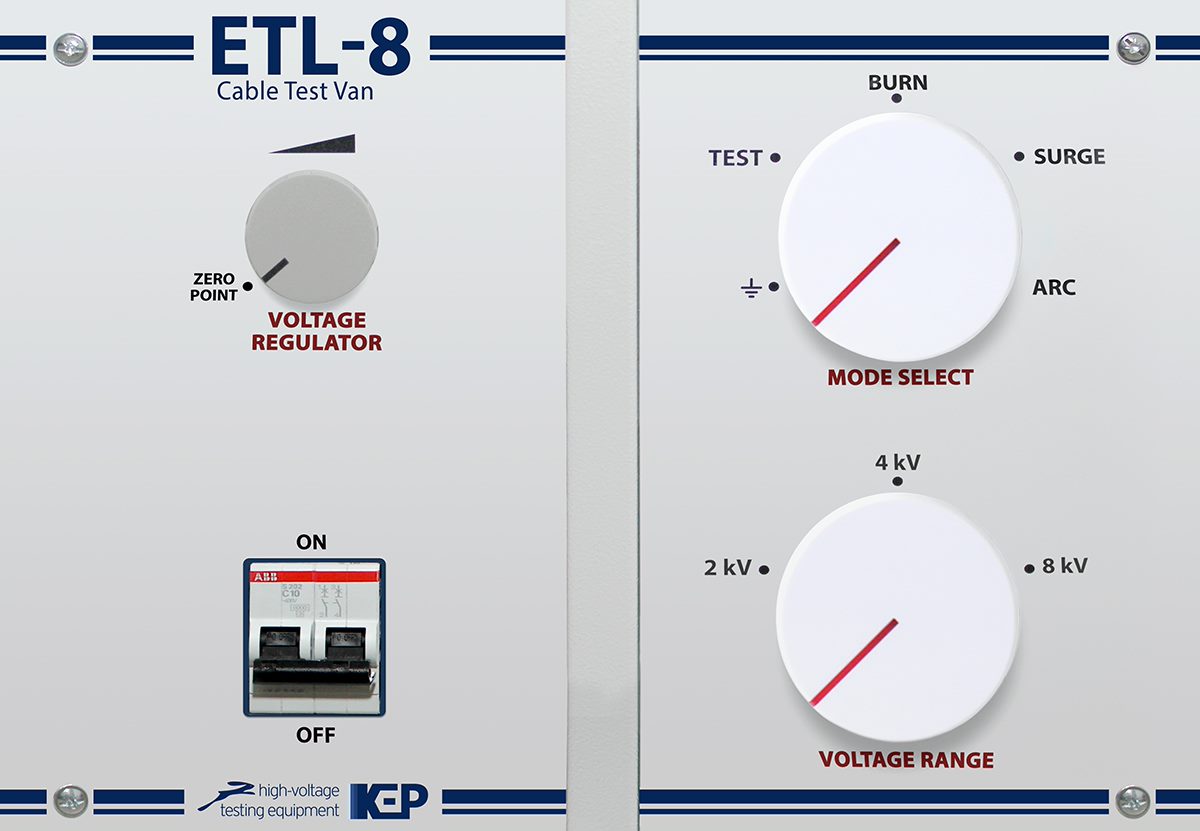

DC TESTING

ETL-8 system allows to carry out cable acceptance tests with DC (rectified) high voltage up to 8 kV.

FAULT PRE-LOCATION

Detachable time-domain reflectometer RIF-9 included with the system is used for determining the distance to faults in electrical power cables with all the main pre‑location methods:

Low-voltage method

- TDR (time-domain reflectometry): low-resistance faults, open cable breaks, various impedance changes characterization (cable sleeves, branches, etc.), total cable length measurement (incl. on a drum or bundle) and cable shortening ratio measurement.

High-voltage methods

- ARC/ARC multi-shot (arc reflection method): high-resistance and unstable faults, minimal harmful effects on a cable.

- ICE (impulse current envelope method): high-resistance faults that cannot be converted to low-resistance by burning faulty insulation.

- DECAY (voltage wave oscillation method): faults with high breakdown voltage.

BURN UNIT

ETL-8 is supplied with burn unit as standard which delivers current of up to 100 mA at up to 8 kV voltage.

Fault conditioning through burning faulty cable insulation is used for converting high-resistance faults to low-resistance so that pre-location and/or pinpointing methods could subsequently be used.

SURGE WAVE GENERATOR WITH A SURGE LEVELS SWITCH

A surge wave generator with up to 1000 J surge energy is used for pinpointing cable faults with an acoustic method.

The generator is supplemented with a surge level switch allowing to select output voltage in the ranges of 0…2 / 0…4 / 0…8 kV, which delivers maximum possible energy of the surge pulses.

SAFETY

All-round operator safety systems built into ETL-8 includes the following modules and devices:

✓ Overvoltage and overcurrent protection.

✓ Overheating protection.

✓ Equipment and vehicle chassis protective earthing.

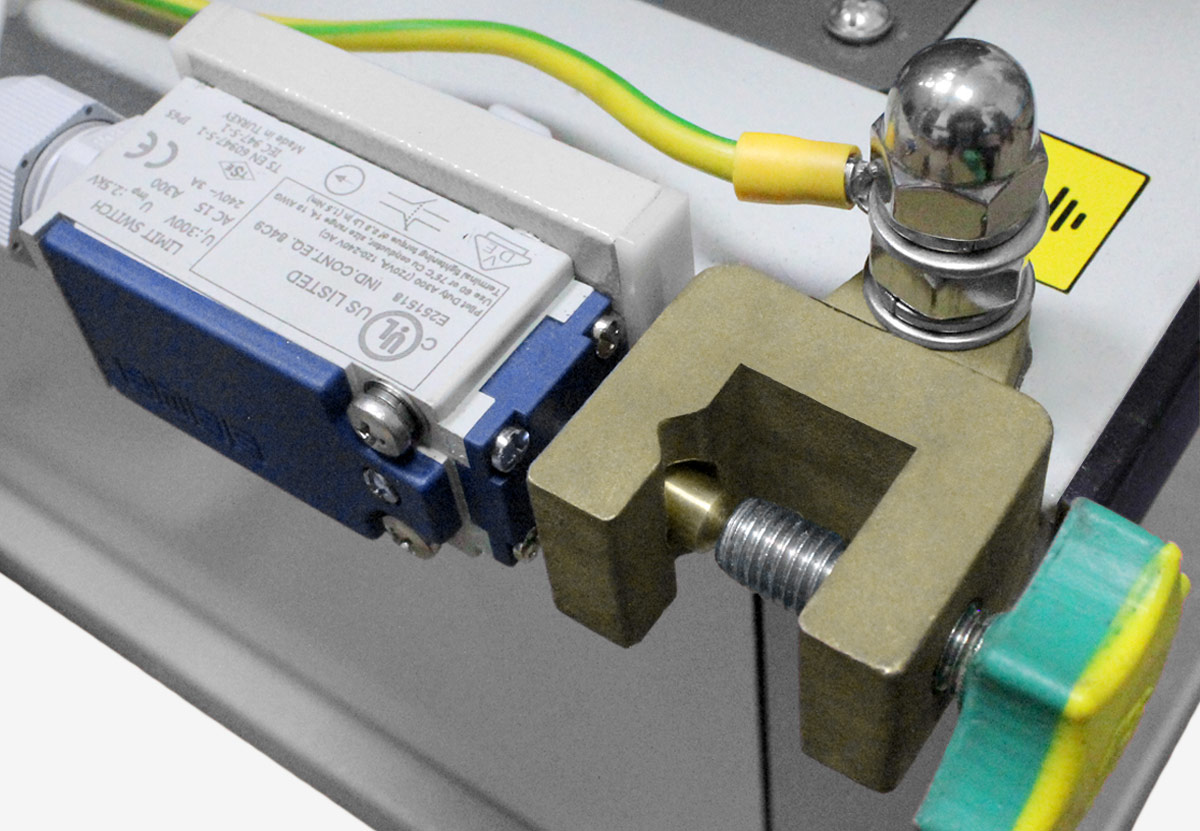

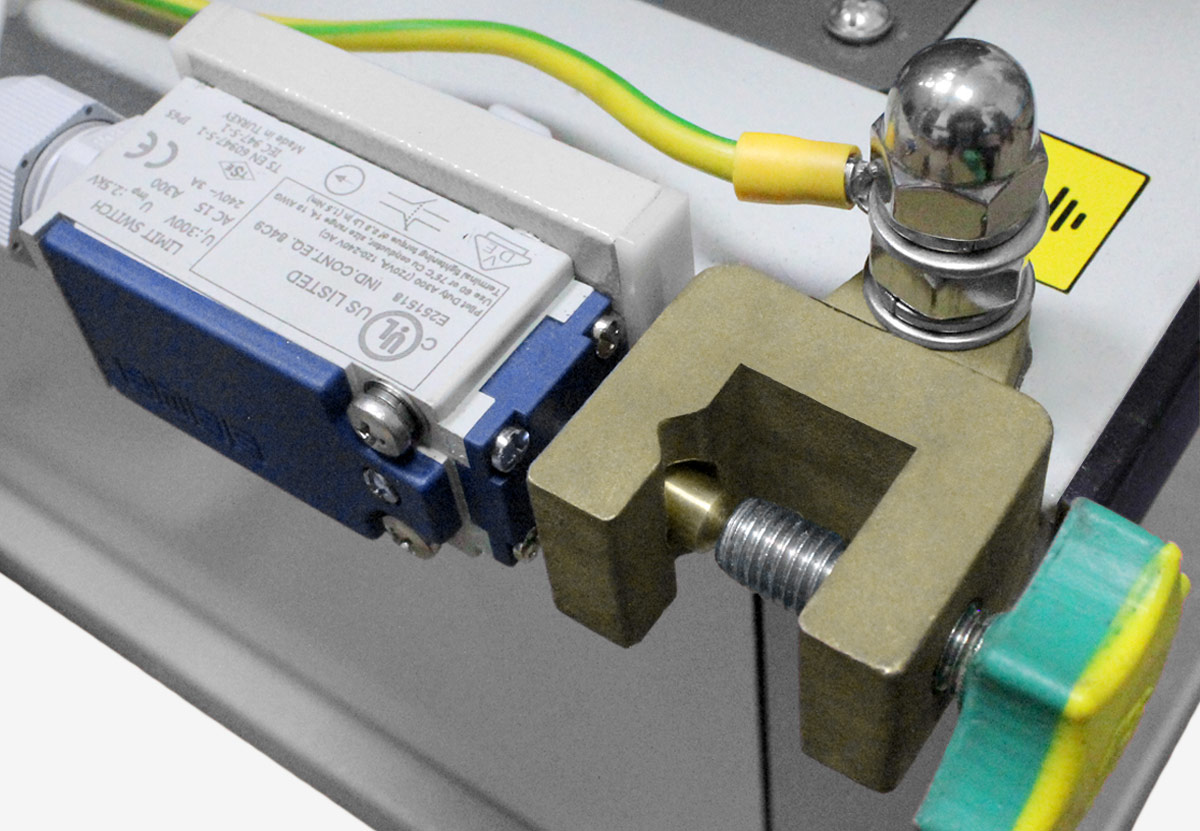

✓ Continuous grounding monitoring system.

✓ Emergency stop button.

✓ Automatic discharge device.

✓ Light and sound indication of high voltage.

✓ Vehicle high-voltage compartment door closure sensors.

✓ Safety ON/OFF keylock switch.

✓ Self-health and safety monitoring of high-voltage switches.

* Products specifications are subject to change without notice. *