HVTS-HP

MOBILE HIGH-POWER HIGH-VOLTAGE TEST SYSTEMS

The HVTS-HP-series systems are designed for high-voltage testing of various dielectrics with DC voltage (up to 140 kV) and AC voltage (up to 100 kVRMS, f = 50 Hz) where a high testing current (up to 80 mA and 175 mARMS in DC and AC modes respectively) is required.

The systems could be used in the field or for laboratory testing.

VERSATILITY

The system features both DC (rectified) and AC output voltage modes, which allows to use a single HVTS-HP system for testing such electrical equipment as cables, current transformers, switchgear, sectionalizing joints, etc. according to various standards and regulation.

HIGH POWER

The power output of HVTS-HP series systems ("HP" means "High Power") is several times higher than that of its analogues.

The output current and voltage at the test object can reach 175 mARMS/100 kVRMS and 80 mA/140 kV in AC and DC modes respectively.

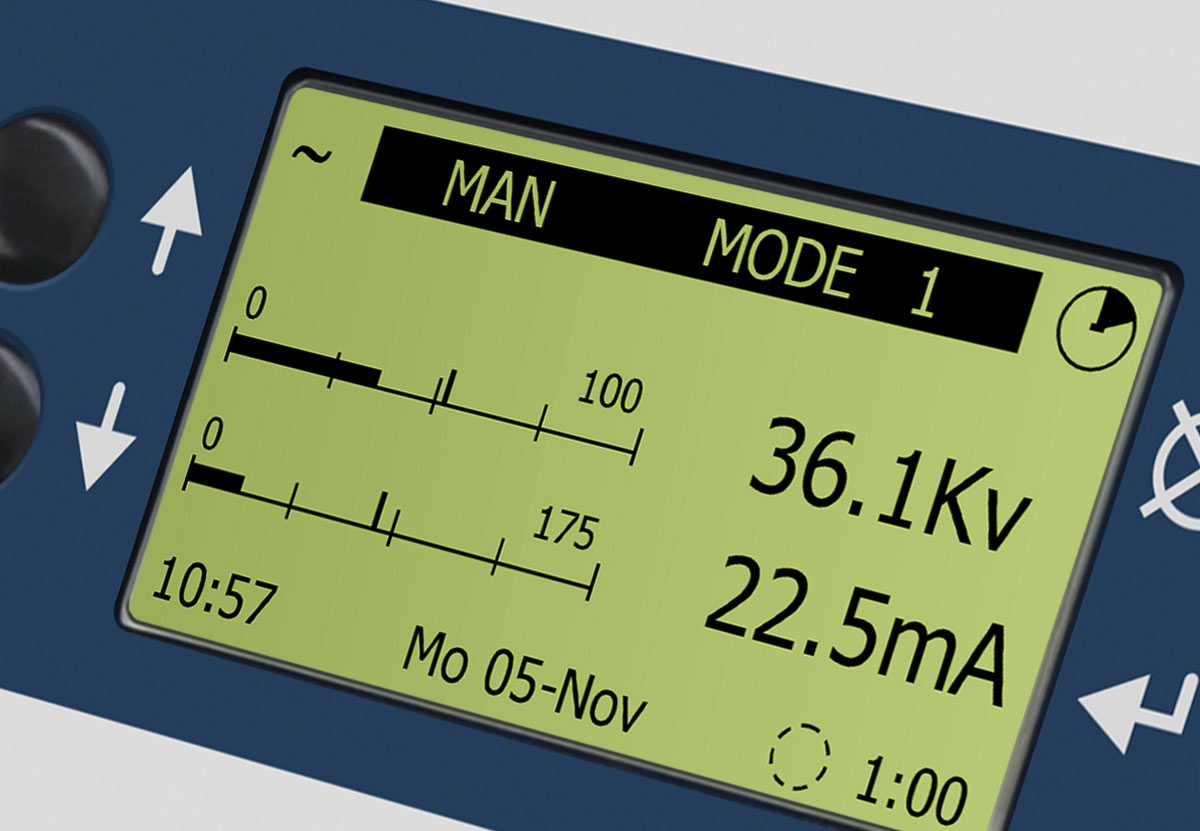

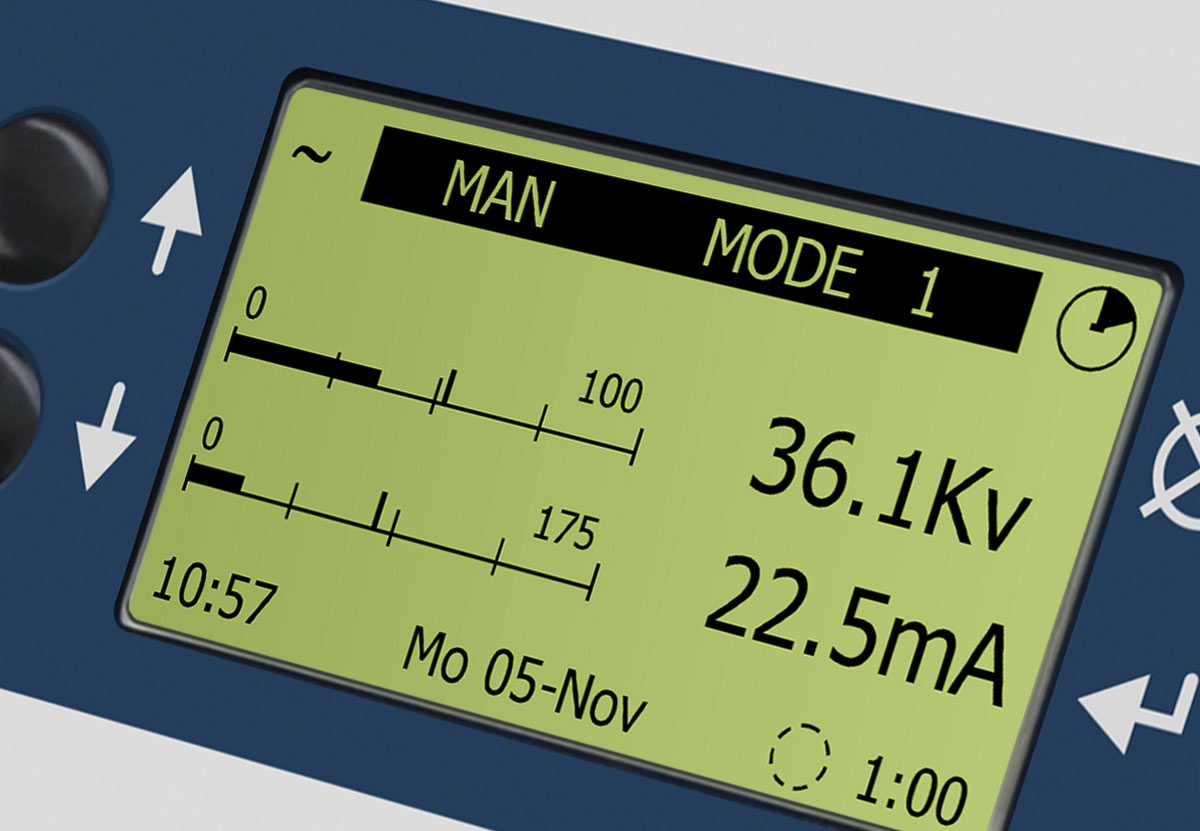

DIGITAL CONTROL

HVTS-HP systems feature a digital graphic display indicating all the test settings and operating parameters.

Digital user interface enables HVTS-HP to feature a multi-language menus, as well as viewing test reports, saving test pre-sets, etc.

MANUAL AND AUTOMATIC CONTROL MODES

The system allows to carry out tests in both fully automatic and manual control modes.

In the manual mode, the output voltage level and ramp up rate are controlled by the operator via a rotary encoder.

In the automatic mode, the test voltage is automatically increased at pre-defined ramp up rate and is held on the required level before being reduced to zero upon completion of the test cycle.

Switching between control modes is done by simple push of a button.

MOBILITY

Light weight, compact size and trolley-form design of both units of the system enable rapid deployment, quick reconnection and operational comfort during the field testing.

SAFETY

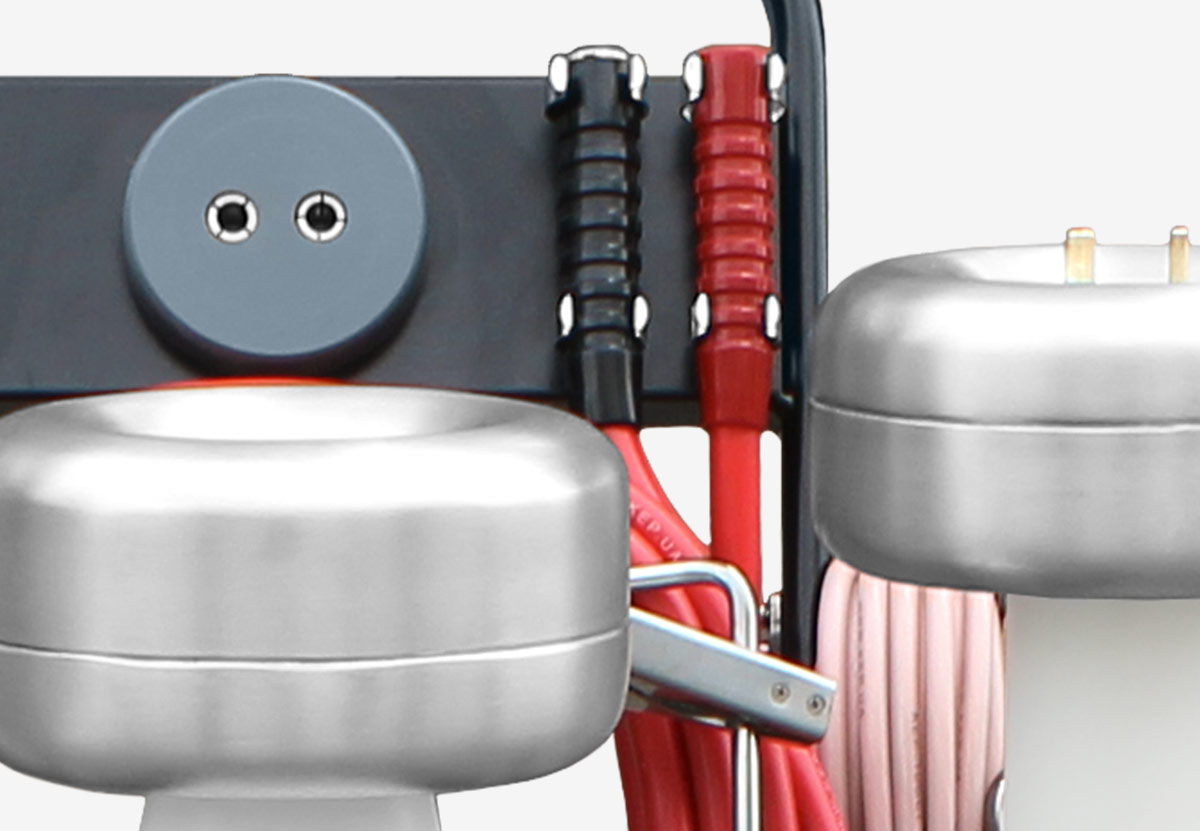

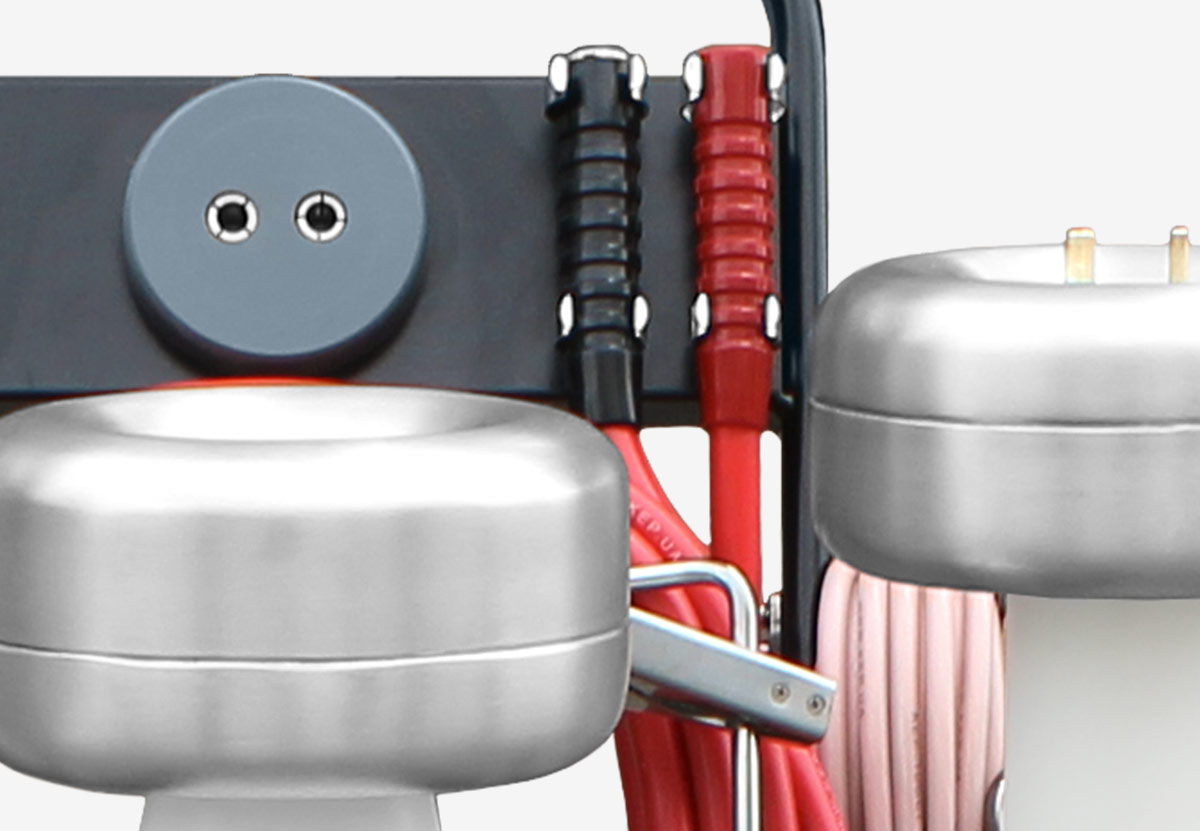

The system consists of two separate modules: the control unit and the high voltage unit.

The test process is controlled from the control unit while an object under test is connected to the high-voltage unit.

Such two-module design allows an operator to remain at a safe distance away from the high-voltage circuit and the object under test.

| HVTS-HP 100/100-7.5 (17.5) | HVTS-HP 140/100-7.5 (17.5) | |||

| DC testing | Output voltage | Adjustment and indication range | 0 … 100 kV | 0 … 140 kV |

| Relative indication error | ± [3 % + 2 dgt*] | |||

| Output current | Maximum level | 40 (80)** mA | 30 (60) mA | |

| Indication range | 0 … 40 (80) мА** | 0 … 30 (60) мА | ||

| Relative indication error | ± [3 % + 2 dgt*] | |||

| AC testing | Output voltage | Adjustment and indication range | 0 … 100 kVRMS | |

| Relative indication error | ± [3 % + 2 dgt*] | |||

| Output current | Maximum level | 75 (175) mARMS | ||

| Indication range | 0 … 75 (175) mA | |||

| Relative indication error | ± [3 % + 2 dgt*] | |||

| Load capacitance @ rated output voltage | up to 2.4 (5.4) nF | |||

| System parameters | Test modes |

■ Automatic ■ Manual |

||

| Voltage ramp rate | 0.5 … 4.0 kV/s, step 0.5 kV/s | |||

| Internal memory | 32 test reports | |||

| Custom test timer pre-set range | 0:10 … 59:59 min | |||

| Interfaces | Display | Monochrome, 128 × 64 px | ||

| Menu languages |

■ English ■ Russian ■ Others (option) |

|||

| Safety | Grounding |

■ Protective earthing |

||

| Protection |

■ Overvoltage ■ Overcurrent ■ Thermal overload warning ■ Low internal gas pressure warning |

|||

| High voltage switch off |

■ EMERGENCY STOP button ■ Power keylock switch |

|||

| Power supply and consumption | Mains supply voltage | 230 VAC, ± 10 % | ||

| Mains supply frequency | 50 Hz | |||

| Power consumption | up to 9 (19) kV•A | |||

| Current consumption | 40 (82) A*** | |||

| Physical | Control unit dimensions, H × W × D | 1063 × 735 × 561 mm | ||

| Control unit weight | 82 (127) kg | |||

| High-voltage unit dimensions, H × W × D | 1012 × 639 × 750 mm | |||

| High-voltage unit weight | 125 kg | |||

* dgt – least significant digit.

** The parameters in parentheses apply to the 17.5 version of the system.

*** Inrush current may be greater. If the System is powered from a power supply source protected by an automatic circuit breaker, a minimum of 63 A (100 A for 17.5 version) breakers are required.